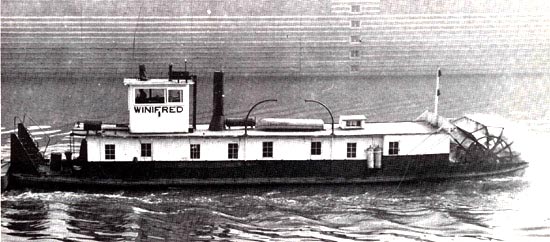

In 1968, Captain William “Bill” H. Price Jr., founded AM&O Towing Inc. as a family company. Captain Bill, at the age of 14, began his river career working with his father, Captain William H. Price, Sr., as a deckhand on stern wheel towboats. Together, father and son did harbor work, consisting of shifting coal barges for an unloading terminal. At the age of 20, Bill Jr. went to work on a 150-HP sternwheeler as a deckhand towing petroleum products, and for the next 12 years, learned the towing, loading, and unloading aspects of petroleum barges. By the age of 21, Bill Jr. was running Captain and began to see the need for good, safe, reliable service for towing on the upper Ohio River system, and AM&O Towing Inc. was born.

After starting with just one towboat, Bill’s company grew over the years to include 15 towboats ranging in horsepower from 500-HP to 2,500-HP. AM&O Towing began handling jobs for Thomas Petroleum Transit and Ashland Oil, and organized Crucible Steel’s coal unloading facility by putting a harbor boat to work. AM.&.O. Towing started delivering #6 oil to Crucible Steel for Ashland Oil, and this marked the beginning of the company’s handling of oil products for many different companies in the Pittsburgh and Huntington districts.

AM&O Towing has since been moving crude oil for over three decades for Quaker State and Ergon in the Pittsburgh and Huntington districts, with millions of miles logged and thousands of locks made without incident.

In 1972, Wheeling Pittsburgh Steel Corp. was in need of a company to handle their coal unloading as well as their steel loading docks and fleets. Through recommendations from Crucible Steel management, AM.&.O. Towing contracted with Wheeling Pittsburgh Steel to handle all of their harbor work and fleeting, and they continue to handle their river operations to this day, 44 years later.

In 1977, J&L Steel of Pittsburgh contacted AM.&.O. Towing about handling their entire harbor in Hazlewood, PA, and subsequently, they were hired. AM&O Towing serviced J&L Steel with two harbor boats for non-stop service, 24 hours a day, as well as a floating crane and six barges to clean leftover coal from processed barges. AM.&.O. Towing worked for J&L Steel for 20 years until the plant’s closing in the late 1980s.

Captain Bill’s son, Steve Price, began his career in 1984 as a third-generation river man as a deckhand on AM&O Towing’s harbor boats. Steve later went on to get his Masters license for towing vessels and passenger vessels. Steve would become USCG certified to weld on tank barges; has training on thermal liquid heaters; completed all course requirements as a Maritime Security Officer; and is ICS100 trained.

In 1985, Steve expanded the family business with the addition of a sister company, Billson Inc., to provide a one-stop shop to the river system. Together, the two companies began building barge docks, unloading dry cargo barges with cranes and excavators, and introduced a fleeting area.

In 1987, DW Dickey and Son contacted Billson Inc. to build a barge-unloading terminal for the unloading of bulk fertilizer. One year later, Billson Inc. was contracted to unload those barges at the terminal and continue to do so to this day for Growmark Corporation.

In 1990, DW Dickey and Son contracted Billson Inc. to build a grain-loading dock and load barges at their terminal, which continues presently with Agland Corporation. Seeing a need for quality marine repairs, three dry docks were added to Billson Inc. to handle boat/barge repairs and steel fabrication. John Fadely and LJ Fadely were brought on board to head the repair division at Billson Inc., and with their excellent reputation and many years of experience, have turned out quality work to many satisfied customers.

It is this father and son’s belief, that with a continued hands-on approach in daily operations, AM&O Towing Inc. and Billson Inc., can continue to provide top-notch service to their customers.